In the world of plastic manufacturing, insert molding and overmolding are two popular techniques that offer unique advantages for creating complex, high-performance products. Understanding the differences between these methods can help you make informed decisions for your projects and leverage our specialized injection molding services.

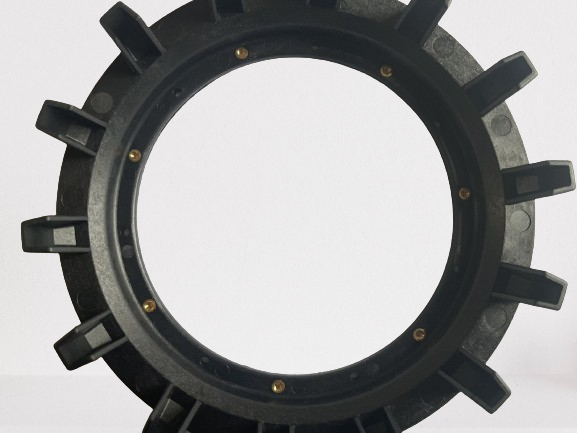

What is Insert Molding?

Insert molding involves placing a preformed component, often metal, into a mold cavity before injecting plastic around it. The result is a single, integrated component that combines the strengths of both materials. This process is commonly used for:

• Metal fasteners in plastic parts

• Electrical connectors

• Threaded inserts

Key Benefits of Insert Molding:

• Enhanced Strength and Durability: By integrating metal inserts, the resulting part has superior mechanical properties.

• Improved Assembly Efficiency: Combines multiple components into a single molded part, reducing assembly time and cost.

• Greater Design Flexibility: Allows for the combination of different materials, enhancing the functionality of the final product.

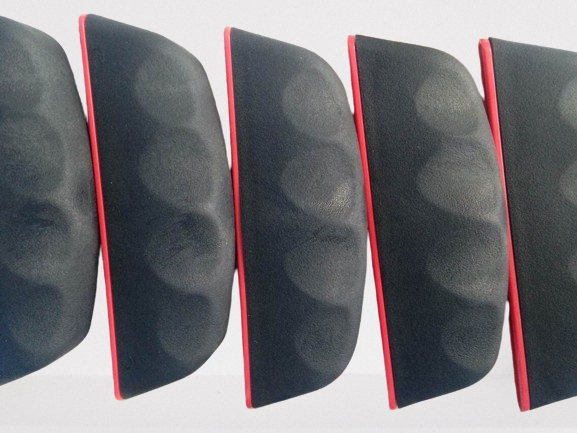

What is Overmolding?

Overmolding is a two-step process where a base material (often a rigid plastic) is molded first, followed by a second, softer material (like silicone or TPU) molded over the first. This technique is commonly used for:

• Soft-touch grips on tools

• Seals and gaskets

• Multi-material components

Key Benefits of Overmolding:

• Enhanced User Comfort and Aesthetics: Provides soft-touch surfaces or ergonomic features, improving the user experience.

• Improved Product Functionality: Combines different materials to enhance the product's performance, such as adding rubber over plastic for better grip.

• Cost-Effective Production: Reduces the need for additional assembly steps by combining multiple materials in one process.

Comparing Insert Molding and Overmolding

|

Aspect |

Insert Molding |

Overmolding |

| Process | Embeds a pre-formed insert within the plastic part. | Molds a second material over a previously molded part. |

| Applications | Metal-plastic components, threaded parts, connectors. | Ergonomic grips, multi-material parts, soft-touch areas. |

| Advantages | Enhanced durability, reduced assembly, flexible design. | Improved comfort and aesthetics, enhanced functionality, cost savings. |

| Challenges | Requires precise placement of inserts. | Managing bond strength between different materials. |

Choosing the Right Technique for Your Project

When deciding between insert molding and overmolding, consider the following factors:

• Material Compatibility: Ensure the materials used in both processes are compatible and will bond effectively.

• Design Requirements: Evaluate the design complexity and functionality needed for your final product.

• Cost and Efficiency: Consider the cost implications and potential savings from reduced assembly steps.

Why Choose TEKO for Your Injection Molding Needs?

At TEKO, we specialize in both insert molding and overmolding techniques, offering customized solutions to meet your specific needs. Our expertise in these advanced molding processes ensures high-quality, durable products that enhance your design innovation.

Our Capabilities:

• Custom Molds: Tailored to your exact specifications for optimal performance.

• Plastic, Rubber, and Hardware Parts: Versatile materials to suit various applications.

• Industry Experience: Extensive knowledge in automotive, consumer goods, construction, and more.

Contact Us Today

Ready to take your product design to the next level? Contact us at TEKO to discuss your project requirements and discover how our injection molding services can benefit you. Visit our website TEKO for more information and to view our portfolio of successful projects.

Call to Action: Partner with TEKO for your next project and experience the benefits of our expert injection molding services. Reach out to us today to request a quote or consultation!